Discover the Versatile Utilizes of Membrane Change in Modern Electronic Devices

In the realm of contemporary electronics, the application of membrane layer switches is incredibly considerable, spanning from streamlined customer devices to critical medical gadgets. As markets proceed to evolve, the assimilation of membrane layer switches in devices style is critical, appealing not just to fulfill yet exceed the rigorous demands of both capability and visual charm.

Exploring the Function of Membrane Changes in Customer Electronics

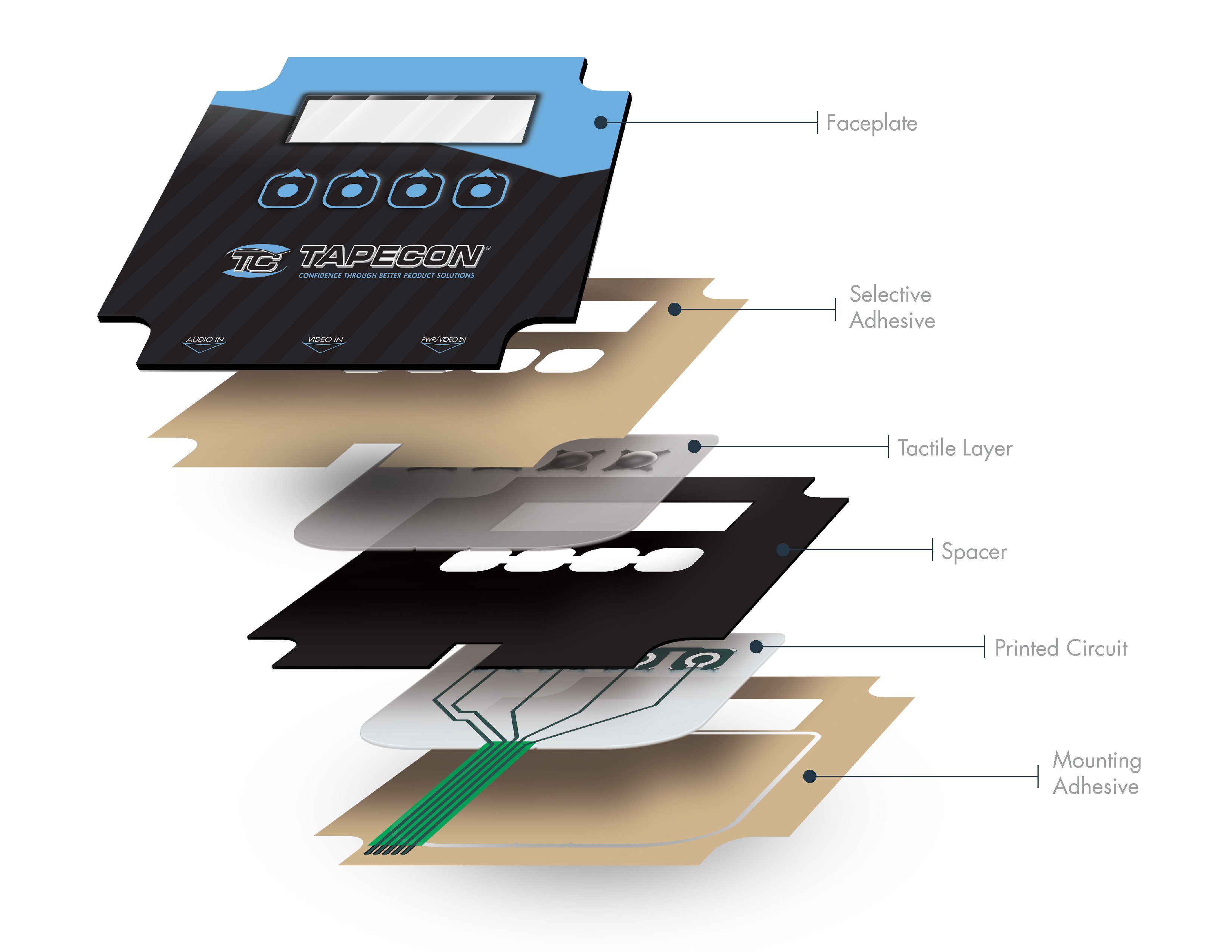

Why are membrane layer switches so common in consumer electronics? The solution hinges on their one-of-a-kind combination of price, reliability, and versatility. Membrane buttons are affordable to produce, making them an attractive alternative for high-volume production common in customer electronics. Their building and construction, including a thin, adaptable layer that can easily be incorporated into different gadgets, allows for smooth, small product styles.

Moreover, these switches are understood for their resilience and low upkeep. They are resistant to dust, dampness, and dust, which boosts the longevity of the digital gadgets they are used in. This dependability is vital in day-to-day customer products that undertake constant usage. Additionally, their convenience in layout enables personalization in aesthetic appeals and capability, accommodating the specific demands of various electronic devices. From microwave to remotes, membrane buttons offer a useful, user-friendly user interface that sustains the dynamic nature of consumer electronics.

Membrane Layer Switches Over in Medical Gadgets: Enhancing Interface

Membrane layer buttons also play a significant function in the world of clinical tools, where they boost interface with their distinctive advantages. These buttons are specifically valued for their dependability and convenience of hygiene, critical in medical care atmospheres where cleanliness is critical. The smooth, covered surface of membrane changes enables very easy sanitation, minimizing the danger of contamination and spread of virus. Moreover, their style flexibility fits the ergonomic and aesthetic needs of clinical devices, making devices more intuitive see post and accessible for health care specialists.

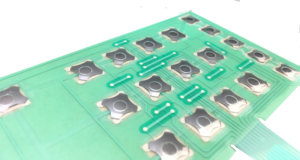

Membrane layer switches additionally contribute to the resilience of medical devices. Their resistance to pollutants and fluids guarantees that crucial devices stays operational in various clinical setups, consisting of surgical procedures where exposure to liquids prevails. This sturdiness, combined with tactile responses and low-profile layout, makes membrane switches an indispensable part in boosting the efficiency and safety and security of medical device interfaces.

The Influence of Membrane Turns On Industrial Equipment Style

In the world of industrial equipment style, the unification of membrane buttons has noted a substantial evolution. The slim profile of membrane layer changes enables for more compact equipment designs, while their resistance to water, chemical, and dirt impurities makes my latest blog post them suitable for industrial setups.

Furthermore, the customizability of membrane layer switches over enables designers to integrate details tactile responses and visual overlays that boost the customer experience and boost efficiency. This combination sustains operators in achieving accuracy control over intricate equipment. The overall influence is a significant improvement in the functionality, integrity, and user-friendliness of industrial equipment, straightening with the enhancing demands for technological improvement and functional effectiveness in modern sectors.

Final Thought

Membrane layer buttons have transformed contemporary electronics, using streamlined, resilient, and personalized interfaces across different fields. Membrane Switch. In consumer electronic devices, they enhance the visual and functionality of tools. Clinical markets benefit from their trustworthy, user-friendly controls, crucial for sensitive settings. Industrial applications value their strength and efficiency. This technology not just satisfies the demanding conditions of various fields however additionally considerably improves individual experience, making membrane switches over a cornerstone of modern electronic design.

In the realm of modern electronics, the application of membrane buttons is remarkably substantial, covering from sleek consumer gizmos to crucial medical tools.Why are membrane layer switches over so widespread in customer electronics? Membrane buttons are cost-efficient to make, making them an attractive option for high-volume production regular in consumer electronic devices. From microwave ovens to remote controls, membrane layer switches provide a practical, easy to use user interface that sustains the dynamic nature of customer electronics.